Central Water Softener – Efficient Softening, Say Goodbye to Scale

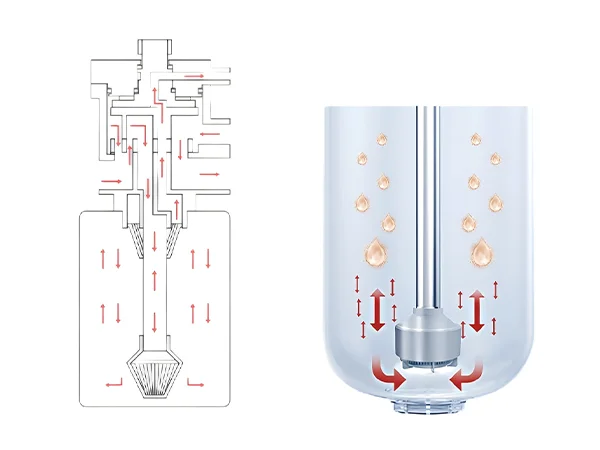

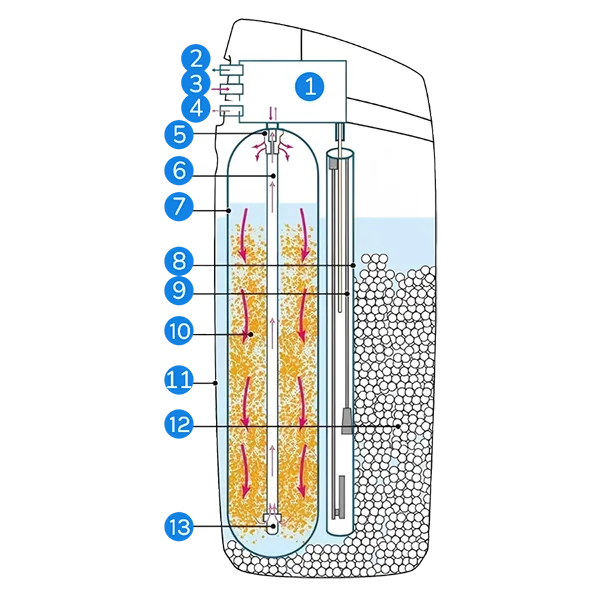

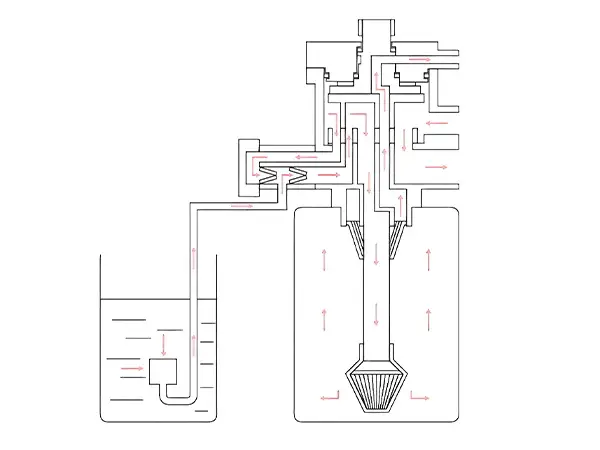

In a whole-house water purification system, the central water softener is typically installed downstream of pre-filters and central water purifiers. Water flows through the ion exchange resin layer inside the softener, where calcium and magnesium ions are replaced with sodium ions through on exchange technology, reducing water hardness and softening the water. The resin regenerates periodically to maintain efficient operation.

A central water softener provides softer, more comfortable water, prevents scaling that can clog pipes and damage equipment, and reduces reactions between impurities and skin oils, leaving skin smooth and clothes softer after washing.