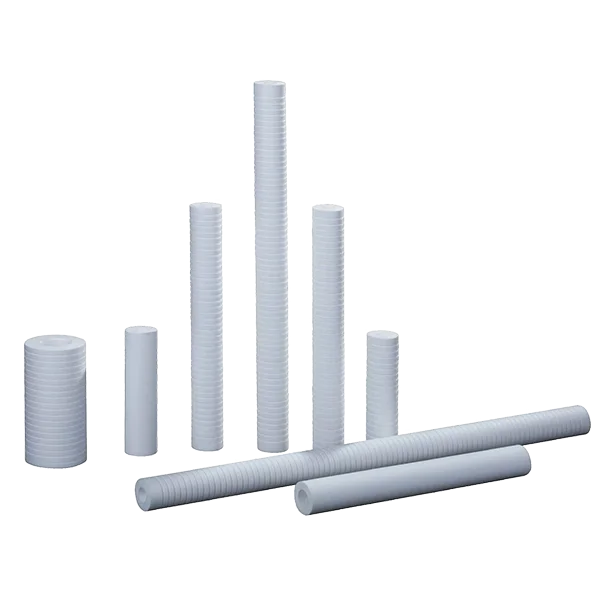

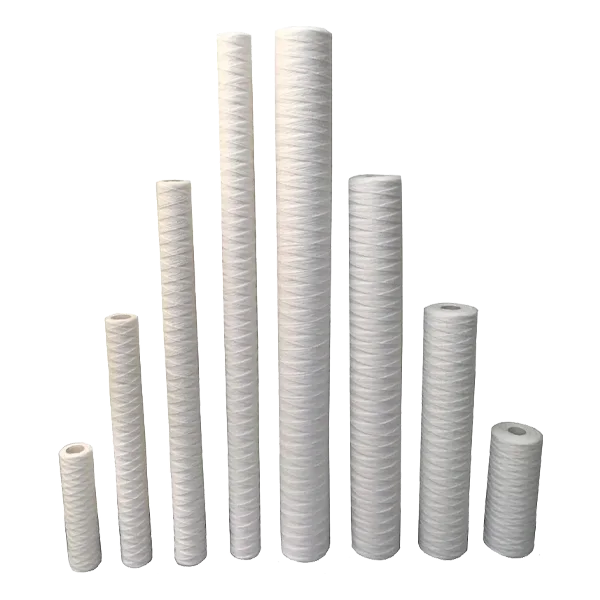

PP Cotton Filter Cartridge – Effectively Intercepting Sediment and Rust

PP cotton filter cartridge is made of non-toxic, odorless polypropylene fiber material, featuring acid and alkali resistance and stable performance. It is commonly used as the first line of defense in water purification systems and is an indispensable core component in water purification equipment, specifically designed to filter sediment, rust, suspended solids, and other large particulate impurities in water. With its efficient, stable, and economical filtration performance, it is widely used in household, commercial, and industrial water treatment applications.