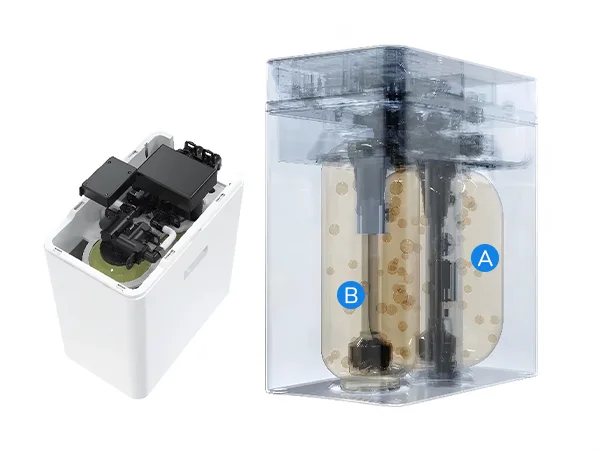

Dual-tank Water Softener – 24-hour Continuous Soft Water, Providing Comprehensive Protection

Unlike single-tank water softeners, dual-tank water softeners have two resin tanks to remove calcium and magnesium ions from the water, reducing its hardness. The two tanks work alternately; when one tank is undergoing regeneration (i.e., restoring its softening capacity), the other tank can still continuously provide soft water. This design allows it achieving a 24-hour uninterrupted supply of soft water, suitable for places that require continuous soft water, such as large residences, hotels, etc.