- Gallon: 50 / 75 / 100 / 200 / 400 / 800 G

The collaborative cooperation of water purifier components builds an efficient and stable water treatment system. Each component plays an indispensable role in the RO system. From the initial filtration of the pre-filter cartridge, to the necessary water pressure provided by the booster pump, to the deep purification by the RO membrane, and the water storage function of the storage tank, all components work closely together. They remove impurities from water, deliver high-quality purified water, and maintain long-term stable operation to meet diverse water needs for both household and commercial applications.

In an RO system, a booster pump is a small electric pump used to increase the water pressure entering the RO membrane. It typically works in conjunction with a solenoid valve and a pressure switch, automatically activating in cases of low water pressure or high water demand to provide stable pressure output for the system. The use of a booster pump not only improves the water production speed and output quality of the RO water purifier but also extends the lifespan of the RO membrane.

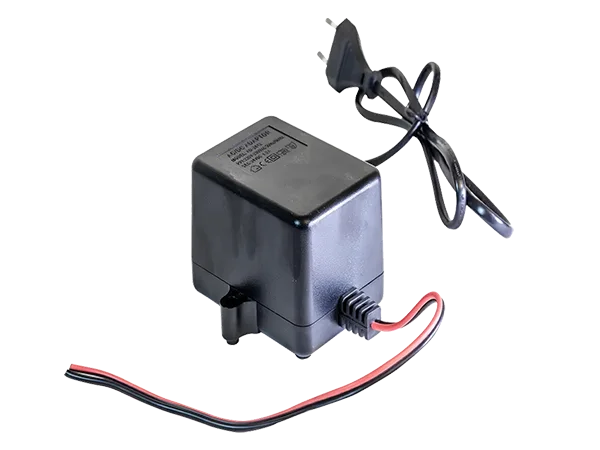

The transformer is responsible for converting high-voltage AC power into low-voltage AC or DC suitable for the system's operation, supplying power to components such as the booster pump, solenoid valve, and control panel. It not only delivers stable voltage but also serves as a safety measure by isolating high voltage electricity. Depending on the system's requirements, the output power and voltage of the transformer may vary.

The faucet is an important terminal component in a water purification system, allowing users to directly access purified water. It connects to the purified water outlet pipe, delivering multi-stage filtered pure water to the user. Compared to standard faucets, those used in water purification systems are designed with a greater emphasis on water quality safety, user convenience, and durability. They are typically made from food-grade materials to prevent secondary contamination.

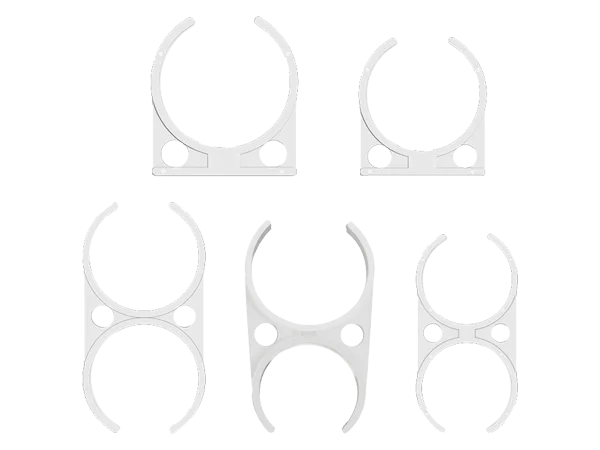

The RO water filter clamp is a small component used to secure filter cartridges. It is made of durable, corrosion-resistant materials and can adapt to humid environments and high water pressure conditions. Clamps come in different specifications such as single and double clamps, and can be selected based on the type and size of the filter cartridge.

TDS represents the total amount of all inorganic salts and a small quantity of organic matter dissolved in water, typically measured in ppm (parts per million). It reflects the concentration of dissolved solids such as minerals, salts, heavy metals, and chlorides in the water, and is a key parameter for assessing water purification effectiveness and monitoring filter cartridge performance, directly impacting the purity and safety of the output water.

TDS-01 TDS Meter

TDS-02 TDS Meter

A pressure gauge is an instrument used to measure and display the pressure within a water pipeline. It is typically installed at the outlet of the booster pump, before the RO membrane, or in front of the storage tank in an RO system. With the pressure gauge, users can monitor the water flow pressure in real-time, ensuring the system operates within the optimal pressure range.